- Home

- Project Solution

- Equipment Solution

VSLM series ultrafine vertical roller mill are mainly used in the following production lines

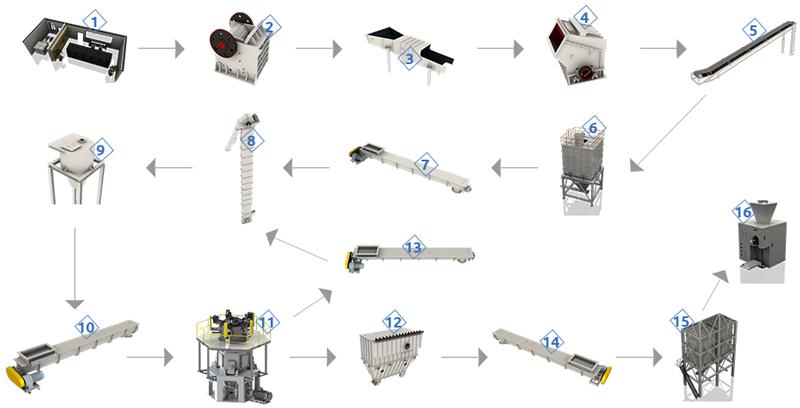

1. Central control room

2. Jaw crusher

3. Ore washer

4. Impact crusher

5. Band conveyor

6. Feed silo

7. Screw conveyer

8. Bucket elevator

9. Transition silo

10. Feed screw conveyor

11. Vertical roller mill

12. Filter bags dust collector

13. Back feed screw conveyor

14. Screw conveyer

15. Finished products stock silo

16. Packaging machine

- PVC Plastic Ultrafine Powder Vertical Roller Mill Line

Introduction of the production line: First, marble or calcite would undergo two stage crushing. The first stage is coarse crushing. The materials are crushed to as small as sizing 5-10 centimeters by the jaw crusher. Then the materials are cleaned by the ore washer.

- Coating and Paint Powder Grinding Mill Line

Introduction of the production line: We use the jaw crusher which can produce 15-20 tons materials per hour to crush the marble or calcite to materials as small as 1-2 centimeters. Then they are sent to the feed bin through the band conveyor.

- Engineered Stone Production Powder Mill Line

Introduction of the production line: We use the jaw crusher which can produce 15-20 tons materials per hour to crush the marble or calcite to materials as small as 1-2 centimeters. After being cleaned by the ore washer, they are sent to the raw material silo through the band conveyor.

- Cable Wire Production Powder Grinding Line

During the grinding stage, the materials are first elevated by bucket elevator to the transit silo for buffering. Then they go through belted scale and screw conveyer. The materials are fed into the main body of the vertical mill continuously and uniformly.

- Barite Powder Grinding Mill Line

The materials are crushed to particles sizing 1-2 centimeters by baffle crusher, hammer crusher or cone crusher. Then they are sent to the feed bin by band conveyor and stored there. During the grinding stage, the materials are first elevated by bucket elevator to the transit silo for buffering.

- Alumina Powder, Magnesium Hydroxide Powder Mill Line

Introduction of the production line: We first use the bucket elevator to raise the raw material (100-600 category aluminum hydroxide) and send them continuously and uniformly to the main body of the vertical mill through the screw conveyor.

- Paper Pulp Mill Line

The bucket elevator raises the materials to the main body of the grinding mill through the screw conveyor continuously and uniformly. After the grinding process in the mill, the materials go through the classifier to get classified according to the degree of fineness of the products.

- Ultra Fine Kaolin Powder Mill Line

Introduction of the production line: The 100-400 category kaolin are sent to the raw material silo through the band conveyor. The bucket elevator raises the materials to the main body of the grinding mill through the screw conveyor continuously and uniformly.