- Home

- Project Examples

- Ultra Fine Powder Grinding Machine Line by Turkey Customers

In October, 2017, the project of Turkish food grade calcium production line with the annual production of 30,000 tons contracted by Dongguan Vsunny Machinery Co., Ltd entered the stage of designing, planning and installation. The production line of this project would adopt the VSLM-XXXX type ultrafine powder grinding mill manufactured by Vsunny Machinery.

Vsunny cooperate with the largest calcium carbonate manufacturer in the world for the first time

As the leader in calcium carbonate manufacture industry worldwide, the customer occupies as high as 70% of the world calcium carbonate market. In that the company's manufacture and business are relatively mature and the non-metal industry is developing well, the customer intends to invest a food grade calcium production line in Turkey.

At the beginning of the year, the Turkish project manager of this customer got the news that Vsunny established the first domestic food grade calcium vertical ultrafine powder grinding mill production line in Guizhou in 2016 and got strongly interested in our vertical ultrafine powder grinding mill. They emailed us many times to consult about contracting out food grade calcium carbonate production line and knew about the production ability and technical parameters of our vertical ultrafine powder grinding mill. They also put forward relative demands of the Turkish project about the property and technology of the vertical grinding mill.

Based on plenty of communication, the customer arranged for personnel of purchase, project, technology and quality department to come to Changping, Dongguan to conduct competency assessment of the factory of Vsunny Machinery. During this process, the customer has had a deep understanding of different aspects of vertical grinding mill manufacture such as the production process design, quality control and progress follow up. They also made relative written records.

At the end of this April, the customer arranged for more than 40 tons of marble to be sent from Changxing, Zhejiang to Hezhou, Guangxi as the raw material for us Vsunny Machinery to test manufacture on the vertical ultrafine powder grinding mill production line of a customer in Hezhou. They also appointed several senior technicians to observe the operation conditions of our equipment. In the factory in Hezhou, the customer and us spent two days completing different kinds of tests. We made detailed records of different parameters during the testing process and the test data of the finished products. During the trial production, many senior technicians thought highly of the technical properties of our grinding mill.

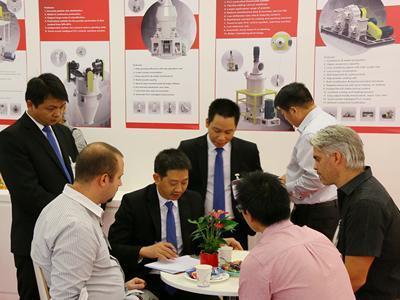

At the middle of August, the project manager and technical team of the customer flied from Europe to China and came to Vsunny Machinery to inspect and have technical discussions. They put forward technical demands about every component on the equipment list. We had long discussion about the problems we are facing such as the pollution of the equipment to material, operation under high temperature and high temperature operating environment. After the discussion, we are more confident to manufacture the grinding mill for food calcium carbonate powder.

At the end of September, on the international powder mechanical processing and analysis technology exhibition( POWTECH 2017 ), which is the largest seminar of powder grinding field in Nuremberg, Germany, the project manager and engineering designing team came to the stand of Vsunny Machinery again to consult about more detailed information which has not been confirmed. Finally, after evaluating our ability, quality, technology, experience and service, the customer decided to make contract with us Vsunny for the vertical grinding mill.

Vsunny is fully capable of helping customers solve the problems and serve the customers' high demand from all perspectives

First, the customer put forward the demand of avoiding causing pollution from the manufacture equipment to the food calcium products. So we discussed many times and studied every detail of the equipment and optimized the process according to the international food processing equipment standards approved by the customer. Any position which have direct contact with the material such as the grease, sealed component, screw conveyor, pipe and the inner part of the main body would use the most proper material. We also raised the standards of surface processing of steel material to meet the requirements of no pollution of food calcium.

Second, the customer put forward the demand that the inlet air temperature of the vertical powder grinding mill and the operation temperature of the vertical grinding mill must reach 200℃. ( In most cases, the inlet air temperature of mill grinding heavy calcium carbonate must be below 60℃, the operation temperature in the vertical mill is about 100℃ ) The local production environment features dry climate and high temperature. The environment temperature in the factory in summer is about 45℃, the highest temperature is nearly 50℃. Also taking the heat produced during the operation of the production equipment into consideration, the property of the grinding mill would be negatively affected. So we attach special attention to the cooling system of the critical stages. We apply optimization and modification processing based on the previous foundation. We also designed grease air cooling device for the lubrication system such as the reduction gear box and the grinding roller.

On the other hand, high temperature working environment raises the demands for the processing precision of the components of the production equipment. Since for the principle of expansion with heat and contraction with cold, the external dimension of the components would change in high temperature environment. We must adjust the processing precision according to the different coefficients of thermal expansion of different material. In order to ensure that the components of the equipment can work properly during the production process, we would simulate practical production environment after the assembly process to test the property of the components under high temperature.

Future plan

The customer is satisfied with our production progress. Besides, the customer also has new projects in the factories in Ukraine, Russia, India and Iran that require grinding mills. At the present they are still consulting the price in the first stage. They intend to purchase equipment such as grinding roller mill and activation modifier from our company which proves the recognition of the customer for our equipment quality, technology and service.